In the recent war between Israel-USA and Iran, uranium centrifuges became a centre of international attention when the USA bombed them in Iran. Luckily, Iran appeared to have taken enough precautions so that no major radiative leak resulted from the bombing.

So what is a uranium centrifuge really?

Uranium enrichment is a crucial process in the development of both nuclear energy and, controversially, nuclear weapons. At the center of this process is a remarkable piece of technology known as the gas centrifuge. This article explores in depth how centrifuges are used to purify uranium-235 (U-235), the rare fissile isotope of uranium that is essential for sustaining nuclear reactions. We will cover the science behind uranium enrichment, the mechanics of centrifugation, the role of U-235, and the global implications of enrichment technology.

1. Understanding Uranium Isotopes

Natural uranium consists mostly of uranium-238 (U-238), which makes up about 99.3% of the total, and a small fraction -- only about 0.7% -- of uranium-235 (U-235). U-235 is the isotope that can sustain a nuclear chain reaction, making it highly valuable for both civilian and military nuclear technologies.

Because U-235 is relatively rare, it must be concentrated or "enriched" to be useful. For nuclear power reactors, enrichment levels of 3--5% are typical. For nuclear weapons, uranium must be enriched to over 90% U-235, a level known as weapons-grade uranium.

2. Why Is Enrichment Necessary?

U-235 undergoes fission when struck by a thermal neutron, releasing energy and more neutrons that perpetuate the chain reaction. However, U-238 is not easily fissionable with thermal neutrons. Therefore, increasing the proportion of U-235 relative to U-238 is essential for both efficient energy production and weaponization.

Natural uranium simply doesn't have enough U-235 to sustain a chain reaction in most reactor designs or to trigger a nuclear explosion. This necessitates the enrichment process.

3. The Basics of Isotope Separation

The challenge in enrichment lies in separating two isotopes -- U-235 and U-238 -- that are chemically identical but differ slightly in mass. Because of their chemical similarity, traditional chemical separation methods do not work. Instead, physical methods that exploit the tiny mass difference must be used. This is where gas centrifuges come into play.

4. Uranium Hexafluoride: The Feedstock

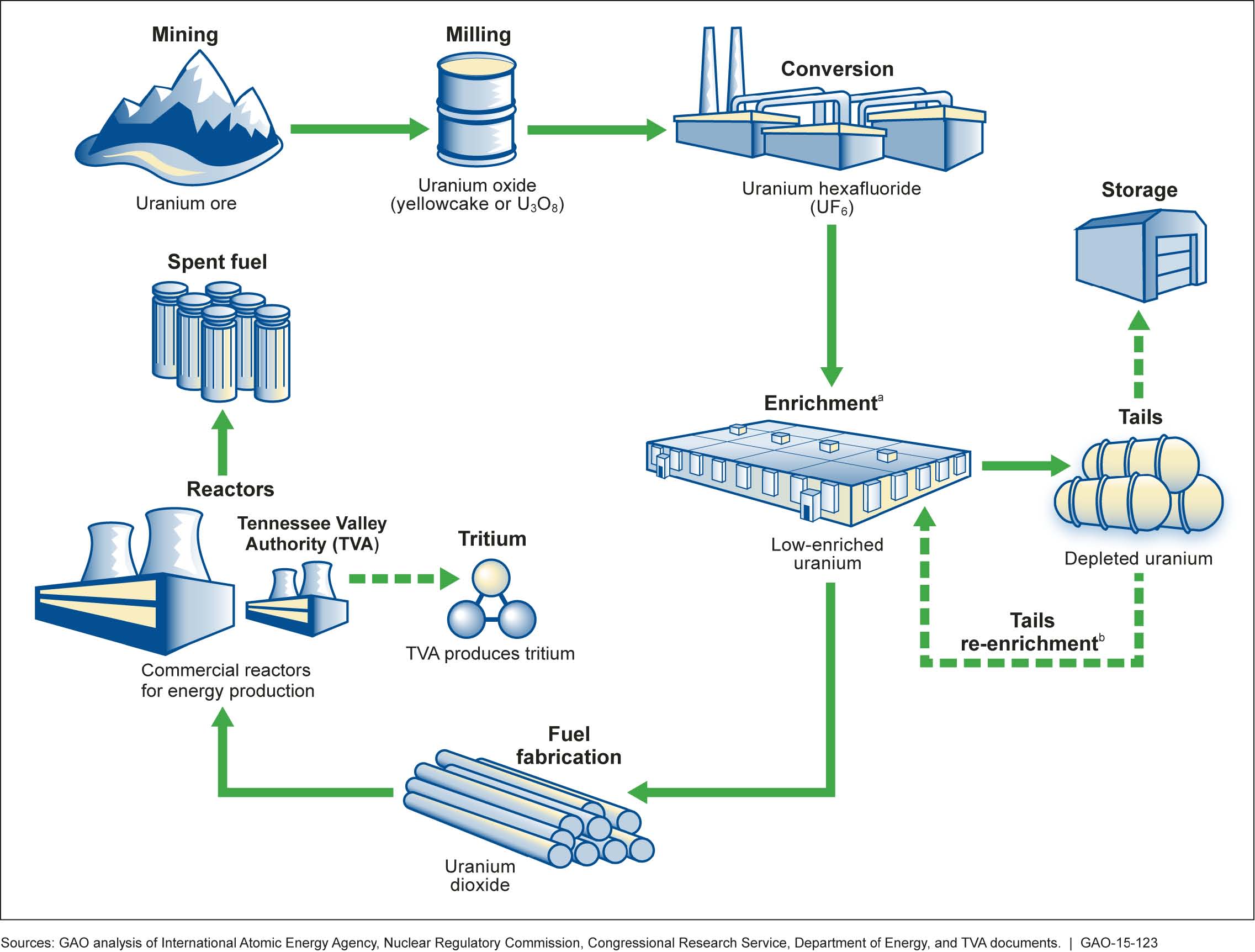

Before enrichment can begin, uranium ore must be mined, processed, and converted into a gas known as uranium hexafluoride (UF6). This compound is chosen because it is the only uranium compound that is a gas at relatively low temperatures, and it maintains the physical and chemical properties needed for centrifuge processing.

The UF6 gas is fed into the centrifuge system, where the actual separation occurs.

5. How Gas Centrifuges Work

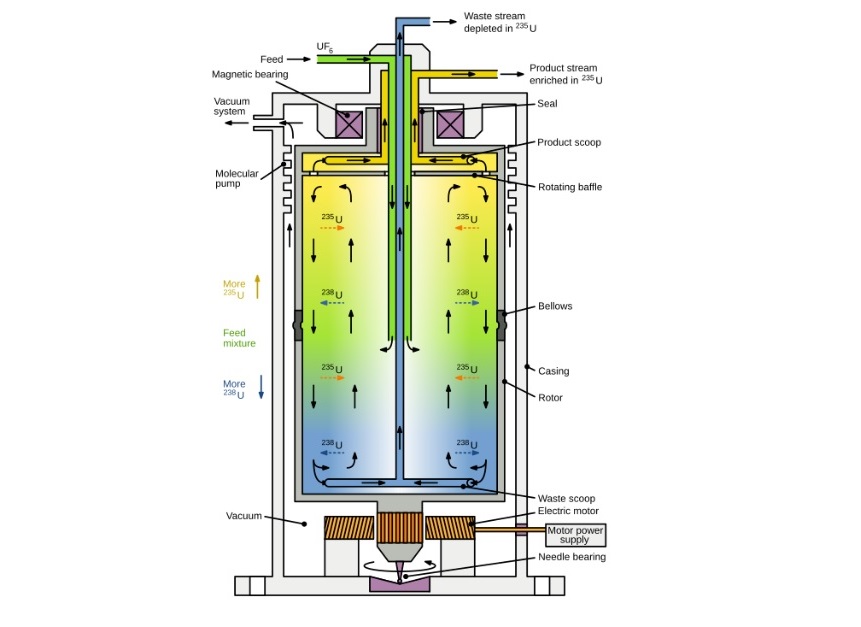

A gas centrifuge is a cylindrical machine that spins at extremely high speeds -- often in excess of 60,000 revolutions per minute. When UF6 gas is inserted into the centrifuge, the rotation generates strong "centrifugal forces" that push the heavier U-238 molecules toward the outer wall and allow the slightly lighter U-235 molecules to remain closer to the center.

In physics, we learn that "centrifugal force" is a fictitious force. So if it is not real, how can it push the molecules? It is because molecules (or anything with mass) tend to move in a straight line unless a force changes that. In a centrifuge where a molecule go round and round, "straight line" means moving away from the circle - towards the outer wall. This makes it look like the molecule is pushed outward by some force.

This subtle separation is collected in two separate streams: one that is slightly enriched in U-235 (the product) and one that is depleted (the waste or "tails"). Because the difference in mass is only about 1%, a single centrifuge enriches the gas only very slightly. Therefore, many centrifuges are connected in series and parallel configurations, forming what is called a "cascade."

6. Cascade Systems: The Key to Efficiency

In a cascade system, gas flows through many centrifuges arranged in a tiered network. Each centrifuge enriches the gas incrementally, with the output of one machine feeding into the next. This gradual process allows the U-235 concentration to be increased to desired levels, whether for reactor fuel or weapon use.

Cascades are designed carefully to optimize efficiency and minimize losses. Engineers must control temperature, pressure, and flow rates with great precision.

7. Advantages of Centrifuge Technology

Gas centrifuge enrichment is favored over older methods like gaseous diffusion for several reasons:

- Energy Efficiency: Centrifuges use far less energy -- up to 50 times less than gaseous diffusion.

- Smaller Footprint: Centrifuge plants are compact and can be hidden more easily, raising concerns about proliferation.

- Scalability: Centrifuges can be added or removed from cascades to scale operations up or down.

8. From Low-Enriched to Highly Enriched Uranium

Centrifuge cascades can be configured to produce different enrichment levels. Low-enriched uranium (LEU) contains less than 20% U-235 and is used primarily in power reactors. High-enriched uranium (HEU), especially weapons-grade (above 90%), requires far more complex and extensive cascades.

HEU production is more tightly regulated due to its potential use in nuclear weapons. The transition from LEU to HEU requires additional stages of enrichment and is a central focus of nonproliferation efforts.

9. Proliferation and International Concerns

Because centrifuges can be used to enrich uranium for weapons as well as for peaceful energy, they are closely monitored by international agencies like the International Atomic Energy Agency (IAEA). A country's ability to develop or conceal centrifuge operations is often seen as an indicator of nuclear ambitions.

The possibility of "breakout" -- a nation quickly enriching uranium to weapons-grade under the guise of civilian programs -- has been a major issue in geopolitical negotiations, such as the Iran nuclear deal.

10. Historical Background

The development of centrifuge technology dates back to the mid-20th century. Early centrifuge efforts were secretive and part of Cold War arms races. Over time, technological advances improved their efficiency and reliability.

Today, centrifuges remain at the heart of enrichment programs in countries like the United States, Russia, Iran, and North Korea.

11. The Science of Isotope Separation Factor

A key concept in centrifuge enrichment is the separation factor, which measures how much more U-235 is present in the product compared to the feed material. The separation factor for a single centrifuge is small -- typically around 1.05 -- but it becomes effective when multiplied across hundreds or thousands of machines in a cascade.

The overall performance of a centrifuge cascade is often measured in "separative work units" (SWU), which quantify the amount of enrichment work done. This metric is vital for comparing the efficiency of different enrichment facilities.

12. Maintenance and Design Challenges

Centrifuges operate under extreme stress due to their high rotational speeds. Balancing the rotors is critical, as any imbalance can cause catastrophic failure. Advanced materials like carbon fiber and precision machining are used to build rotors.

Additionally, the systems must handle UF6, which is corrosive and toxic. Any leaks or contamination must be carefully controlled.

13. Military and Civilian Uses

Civilian uses of enriched uranium include power generation in pressurized water reactors (PWRs) and boiling water reactors (BWRs). Research reactors and naval propulsion systems (e.g., for submarines) may require higher enrichment levels.

On the military side, enriched uranium is a component of nuclear warheads and certain types of naval reactors. This dual-use nature is a major cause of international concern.

14. Future Technologies and Alternatives

New enrichment technologies, such as laser isotope separation, promise to be more efficient and even harder to detect. However, gas centrifuges remain the dominant method today due to their proven reliability and efficiency.

Research is also ongoing into alternatives to U-235, such as thorium-based reactors, which may reduce the need for uranium enrichment in the future.

Conclusion

The use of centrifuges to purify uranium-235 is one of the most important -- and sensitive -- technologies in the modern world. It lies at the intersection of energy, science, and global politics. Understanding how centrifuges work and why they are so crucial to both power generation and national security allows us to better grasp the complexities of the nuclear age.

As geopolitical tensions continue to rise and nuclear proliferation remains a pressing issue, the global community must stay vigilant about how centrifuge technology is developed and used. Transparency, regulation, and diplomacy will be key to ensuring that the benefits of nuclear energy are realized while minimizing the risks of nuclear conflict.

You can learn these concepts and more at Dr Hock's maths and physics tuition.